No one knows the precise region of the world where the hearty olive trees were first grown. Regardless, there is no debate that the dry and sunny shores of the Mediterranean Sea are where wild olive trees grow most bountifully.

Olive oil’s historical roots run deep, with the earliest records of cultivation dating back to 4000 BC along the Mediterranean.

A 1944 artist's rendering on how ancient Greeks may have harvested olives for oil.

Illustration by H.M. Herget.

how it began

In the beginning, olive oil was obtained simply by squeezing the olives by hand or treading them underfoot. This manual extraction process produced only a limited amount of oil, so the yield was used mainly for balms, perfumes, and ointments.

As civilizations advanced, new methods evolved, including the mortar and pestle. The earliest known evidence of their use, dating from circa 2500 BC, was discovered in the region of what was then called Palestine.

The Process was Crude but Effective

- The olives were first reduced to a paste in the mortar.

- The olive paste was enclosed in a crown of olive branches to keep it confined.

- The paste was then pressed on large flat stones piled on top of one another, effectively squeezing out the oil from the olive.

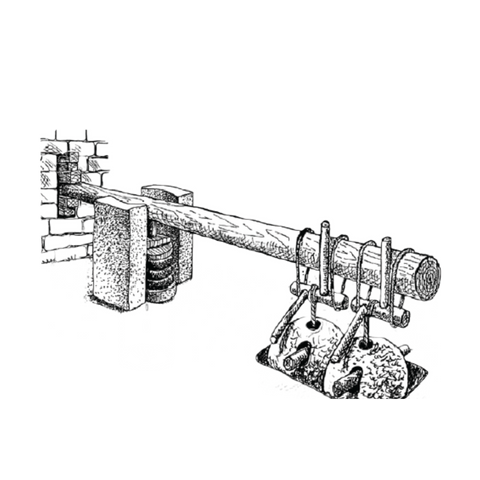

Ancient olive press. The weighted beam pressed on discs full of olive paste.

Though this extraction method may seem primitive, the same principle still applies today. In order to obtain a high-quality, “extra virgin” grade olive oil, a strict harvesting protocol must be coupled with a rigid extraction process.

our extraction process

Harvest

- Our olives are harvested in early November when they just start to change color but are still slightly unripe. Our Arbosana variety is picked as it reaches a soft purple hue, and our Arbequina variety is harvested when it reaches a greenish-purple color. Harvesting the olives at this specific stage ensures the highest level of polyphenols for our oil. The color of the olive and the precise timing of harvest varies from year to year based on weather patterns.

- The fruit is machine harvested using a grape harvester since our olives are more durable and super high density.

- The harvest is quickly transferred to bins and taken to the mill to be pressed. Our oil is pressed within 12-24 hours of harvesting, ensuring our product is of the highest quality.

Ancient writers were keenly aware that time was of the essence and just how quickly olives could spoil.

The Italian philosopher Cato wrote,

“As soon as you collect them, you have to process the oil from the olives before they spoil… Think of the rains which fall every year and make the berries drop to the ground. If you collect them early and are prepared to stock them, you won’t have any damage, and the oil will turn out to be green, and the best. If you leave them on the ground too long, or on a table, the olives will start to go rancid, and the olive oil will stink…”

Milling

- The first step in the oil extraction process is cleaning the olives by removing the stems, leaves, and debris from the fruit. The olives then receive a quick dip in cold water to ensure they are thoroughly cleaned.

- The olives then enter a hammer mill, where they are quickly pulverized into a paste-like consistency.

- The process of making the paste is called malaxation (kneading, rubbing, or massaging a substance to softness). This is done for 20 to 45 minutes, allowing small oil droplets to combine into larger ones. Some manufacturers will heat the paste or add water at this stage to “bulk up” their harvest. At Zimms Organics, our farm partners refrain from this shortcut, as this would result in much lower-quality oil.

- The paste is then transferred to a centrifuge, which separates the oil from the water and solids.

- The pure extra virgin olive oil (EVOO) is transferred to temperature-controlled steel tanks, from which oxygen and light are not able to penetrate until it is ready to be finally bottled and packaged as the finished product.

- The first press, also known as Olio Nuevo, is bottled into small batches as it is meant to be used within a few months. The Olio contains natural sediment from the pressing which may contain more healing properties but also spoils the oil in just 3-4 months rather than 18-24 months. This gives the Olio Nuevo a smaller window of time to be enjoyed, making it a true delicacy to be cherished by many.

- For larger production, the olive oil sediment naturally falls to the bottom of the stainless steel containers, a process which typically takes 4-6 weeks.

- Finally, the olive oil is bottled and ready for consumption. Yum.

Olive oil has been cherished for centuries and was one of the most prominent ingredients used in the ancient world. Our ancient ancestors went to great lengths for just a few drops of this precious liquid gold, which was reserved only for an elite few.

Thanks to major technological advances over the centuries, what began long ago using primitive harvesting and processing methods, has now become both ubiquitous and affordable and can universally be enjoyed by everyone, not only along the Mediterranean Sea but now “from sea to shining sea.”

References:

Lanza, Fabrizia. Olive: A Global History.